BG5k Fabric Belt Rip Detector

Non-Contact, Any Speed or Product, Any Belt Width or Length and Tracks Belt Wander

About the BG5k Fabric Belt Rip Detector

The BG5k ultrasonic rip detector is an inexpensive non-contact solution to detecting rips using a change of belt width coincident with a rip. The device is not belt manufacturer dependent and requires no embedded loops or antennae installed in the belting. . The tear detector is designed to be installed after each load point and can be connected to sites' network via 4-20mA outputs and/or via TCP/IP.

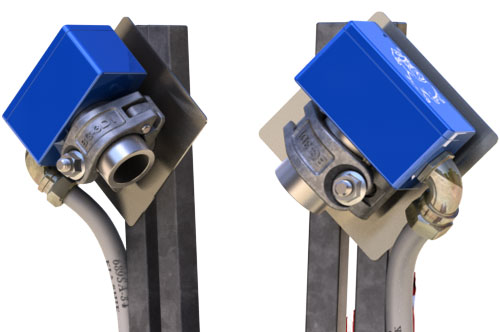

How it Works: The Belt Guard BG5k provides a non-contact method of detecting a longitudinal rip in conveyor belting by monitoring the width of the belt, sensing a change in that width and operating a relay when a specified change in the width of the belt has occurred. The relay may then be used to stop the belt by sending a HALT signal to the Conveyor's PLC and shutting the conveyor down. Strategic location of a number of these devices may limit the length of a rip to within acceptable lengths. Non-contact monitoring of the belt width is achieved through the use of two Ultrasonic Probes, which are constantly sensing the belt edges. When a longitudinal belt rip occurs, the torn sections of the belt commonly move away from each other, due to the product on the belt forcing the sections apart or the torn sections fold over each other and drop towards the bottom of the trough, due to the angle and centring forces of the wing idler rollers. Should either of these two events take place, the width of the conveyor belt will change and a belt rip signal will be generated, which energizes the HALT RELAY.

Belt Tracking / Wander An additional powerful feature of the BG5k is its Belt Tracking or Wander measurement capability. Tracking the lateral movement of the belt on its structure is vital, where product spillage is an issue. If a belt wander trend is detected early, remedial action can be taken to avoid product spillage. The BG5k can sense lateral movements of less than a Millimeter and can provide alarms when certain thresholds are reached, allowing sites to change operating parameters in real-time to minimise the effect of belt wander.